The MAD Guide to Smoking Foods

Over the past decade, smoking foods has experienced a resurgence in kitchens around the globe. At first blush, these techniques seem simple and primitive (and in many respects, they are), but a plethora of variables, details, and scientific concerns come together to make the matter of smoking foods a potentially confusing one. Learning to navigate these challenges can unlock a world of new flavors.

To introduce the uninitiated to the practices of cold and hot smoking, as well as all the ways you can enhance and preserve your food, we enlisted the help of Nordic Food Lab researcher Guillemette Barthouil — who comes from a family of French smokers — to develop a primer for cooks, chefs, and enthusiasts interested in jumping in. Here it is:

My granddad came to Denmark in the 1950s to learn how to smoke. The rivers in South West France, l’Adour and les Gaves réunis, were full of wild Salmo salar (Atlantic Salmon). When these salmon returned from a long swim to the Labrador strait, locals would catch them swimming upstream but wouldn’t preserve them. For centuries, confit had been a popular method for preserving the meat of ducks, pork, and other animals in this region, yet for some reason, no one ever thought to confit salmon.

That includes my grandpa. He wanted another technique to use on the salmon, so he looked north, to a territory that used smoke instead of fat. In the humid and cold land of Scandinavia, smoking — by increasing heat and lowering humidity — enabled food to dry up more quickly. This technique alone was not enough to avoid spoilage, but employed in conjunction with salting, it could keep food throughout the winter.

This interdependence between salt and smoke becomes evident while exploring different Scandinavian food traditions. In some parts of Norway and Sweden, where salt was not available, the water activity and microbial growth could not be reduced enough, and so fish was lacto-fermented — the transformative microbial process that makes kimchi and sauerkraut, among myriad other products — instead of smoked. Pungent surstromming, rakfisk and the more ancient gravlax emerged from this landscape. Where salt was available, however, smoked products were preferred.

For countless generations, humans and their ancestors have burned close to 1500 different species of plants specifically for the smoke they produce. Many — like tobacco and cannabis — are used for medicinal or pleasurable purposes. Others carry hallucinatory substances in their smoke and are used during religious rituals. These are among the oldest known uses for plant-derived smoke. But other plants have been burnt for ages in an attempt to drive away annoying pests and evil spirits, as well as to preserve foods from annoying microbes.

Over millennia, fire has enabled us to explore new foods and expand our diets, and has therefore played a fundamental role in our own evolution and development. That’s another reason for our deep enjoyment of smoked food: the unconscious but very powerful love for the smell of available nutrients.

Nowadays, chefs all over the world are using smoke to add a new dimension to their cooking, which is an exciting development. But smoking food well is about a lot more than just letting a bit of wood burn. To get the most out of this technique in the kitchen, we need to understand more about smoke and how it works.

THE BASICS

Smoke is not a simple gas. It is a mixture of three states of matter: an aerosol of solid, liquid, and gaseous particles. These gaseous particles — chemicals in a vaporized state — only account for 10% of the total volume of smoke but do more than 90% of the work. These molecules influence color, flavor, texture, and preservation, so one should familiarize themself with them. In order to do that, one needs to understand the nature of burning fuel, the necessary conditions of combustion, and how to achieve a controlled regulation of these variables.

Wood has been the smoke-producing plant most used to protect food from spoilage. Its usefulness is mainly due to its structure. A tree is composed of three primary materials. In a wood cell, we find micro-fibrils of cellulose (40 to 50%) and hemicellulose (15 to 25%) impregnated with lignin (15 to 30%). The first two materials are very similar: cellulose is a long linear chain of glucose, while hemicellulose is a shorter, branched chain of various kinds of sugars, not just glucose. Lignin, on the other hand, is one of the most complex natural substances, and its main characteristic for smoking is its intricate network of phenolic molecules.

Fire possesses the ability to liberate many of the fragrant and therapeutic chemicals that are locked up in these three substances. This process of release is called pyrolysis – the thermochemical decomposition of organic matter brought about by high temperature.

Breaking down cellulose and hemicellulose creates a Maillard-type reaction that generates a yellow-to-dark-brown color. Smaller, volatile molecules are also produced, and they give the product its sweet, bread-like, nutty, and flowery notes. This decomposition also unlocks acids that lower the pH of the food surface and slow bacterial growth.

Breaking down lignin contributes other characteristics. The phenols in lignin are a type of antioxidant that retards the rancidification of fats – very useful when dealing with meats, fatty fish, and other fatty substances. Pyrolysis of lignin also creates fundamental flavor compounds – carbonyls and phenols that adhere to the product’s surface and diffuse into it, bringing clove, peat, vanilla, and spicy notes.

Capturing these desired smoking effects depends mainly on the smoldering temperature of the wood, which is in direct relation to the smoldering rate. We can control smoldering rate – and therefore temperature – mainly through airflow. When your combustion is producing flames, the temperature is too high and the airflow should be decreased. And if your burning material is not glowing, you need to increase the airflow. Other important factors that affect smoldering temperature include moisture, the type of wood, and the size and shape of wood shavings.

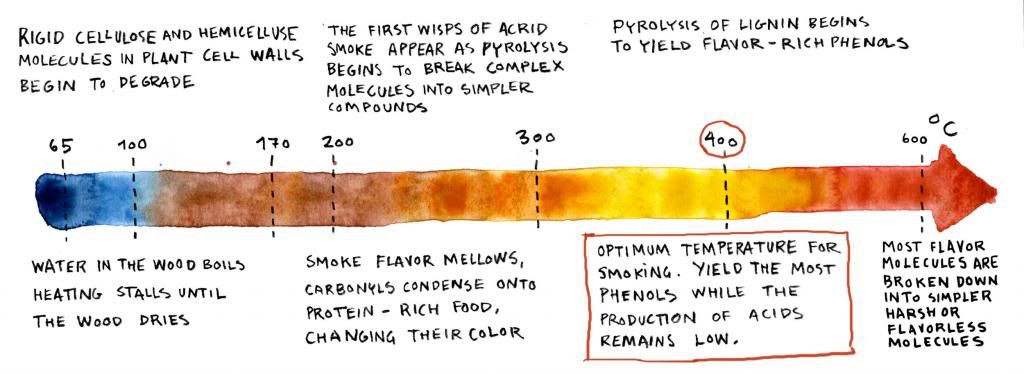

Knowing how to control pyrolysis through these variables is the key know-how of a good smoker. 400°C seems to be the best smoldering temperature to achieve a balance between the sweet and acidic molecules from cellulose and hemicellulose and the stronger phenols from lignin. At higher temperatures, these flavor molecules are broken down into simpler, harsh, and ultimately flavorless compounds. At lower temperatures, especially under 200°C, cellulose and hemicellulose degrade into acetic, formic, and other acids. These acids play an important role in preservation, but in large amounts, they will make the product taste acrid.

For more information about pyrolysis, take a look at our research blog.

Here are some other important considerations:

Bark or no Bark? That is the question. Bark accounts for 10 to 15% of the total weight of a tree and has a much more complex composition than wood. For the purposes of this article, there are important differences between outer bark and inner bark. The dead outer bark usually contains less cellulose and more lignin then the inner bark and is therefore likely to give a harsher taste to the smoked food. In order to further protect the tree, there is a significant amount of acidic compounds in the outer bark that will add an acrid taste. So, for a milder and more balanced smoke, it is better to get rid of the outer bark – but it all depends on the taste you want to give your product.

Hardwood vs. Softwoods. Many people say one should never use softwoods for smoking. I take issue with this, because it obscures the scientific knowledge necessary to make our own choices as chefs and food producers. As with the bark issue, it all depends on how you use the softwood and what type of taste you want to emphasize in the final product. In the temperate Nordic region, softwoods generally correspond to conifers and evergreens, and hardwoods to deciduous trees. Softwoods have a higher lignin content and contain more resinous acids. Lots of lignin means more chances to develop harsh and acrid flavors, which is why most people say to steer clear of softwoods in the smoker. However, if you are careful to keep your pyrolysis temperature around 400°C and do not smoke your product too long, you should by all means use these woods if their fragrant flavors fit with your dish.

The key in this case is that smoking is not only about choosing a flavorful wood for your food, but also about knowing how to extract its wanted characteristics.

Herbs and other kinds of dry grasses like hay have been less used traditionally. When they are, they tend to only be used in small amounts along with wood to enrich the flavor of the smoke. These plants have a very low lignin content and are therefore (as you will probably guess by this point) not that useful for preservation. They are rich in essential oils, however, and thus have great gastronomic potential if your main concern is flavor. When using herbs and grasses, be careful to burn them at neither too high temperatures nor too low — just as with wood — to achieve optimal results.

All of these techniques are indispensable to achieving a delicious and balanced smoke taste that will enhance the flavor of your product instead of covering it. Burning the landscape uncovers a whole new palette of flavors that can enhance many foods and maybe even conjure up your more primitive self in the process. As a cooking technique, smoking gives us the opportunity to use our senses and knowledge to make what is around us taste even better.

COLD AND HOT SMOKING

Cold smoking: One of the oldest preservation methods. It is defined as the process of applying smoke in a chamber between 15 and 30°C, so the smoked food does not cook. There are many different cold-smoking techniques, though it is widely recognized that the healthiest and most balanced in flavor use indirect smoke generation. This means that the smoke is produced in an external chamber — with the temperature of the pyrolysis best at around 400°C — and then travels through a pipe to the chamber where the food awaits.

Smoke reaching the mackerel that hang at the top of a vertical cold-smoking chamber (Credit: Nordic Food Lab)

The smoke cools down during transit, with only the most volatile and delicate molecules of your burning material penetrating the food in the smoking chamber. The refined taste of cold smoking depends also on the humidity of the burning fuel. Pyrolysis of wood that is too wet does not produce fragrant and antioxidant phenols, instead giving way to too many acids that impart an acrid flavor. For cold smoking, the wood moisture is best between 16 and 20%.

But the quality of the final product does not only depend on the smoke you produce. The humidity of the food itself is crucial: if it is too dry, the Maillard-type reactions will not occur and the smoke will not penetrate the food; if it is too wet, it will not color nicely due to a lower rate of Maillard reactions, and flavors will be absorbed unevenly. For this sake, professionals agree that the humidity in the smoke chamber should be between 75 and 85%. This is one of the reasons why smoking is typical of humid areas like Scandinavia. Under these conditions, the food does not dry out so quickly or form an outside crust.

A curious application: at Arzak, in San Sebastian, the development kitchen staff say they cold smoke a preparation of grilled bonito and nuts with cinnamon as the dish hits the table. This has a strong theatrical quality, but the flavor of the cinnamon does manage to penetrate the fish.

Hot smoking: Nowadays, smoking is not seen exclusively as a method of preservation. More and more, it is valued for its ability to produce flavors that can reflect the landscape of a region. While cold smoking achieves both preservation and transmitting the taste of an area, hot smoking is mainly used for flavor. With hot smoking, food is exposed to smoke for anywhere from a couple of minutes to a couple of hours, and the product does not dry out as much as with cold smoking.

For hot smoking, it is best to use wet or freshly cut wood. The latter contains 40 to 60% moisture, so when fresh wood is not in season, you can rehydrate wood to this moisture content. Wet wood seems to produce more smoke, but this is not the case. The extra amount of smoke is nothing more than water vapor (steam) mixed with smoke. That’s the main reason for using this kind of wood, as you don’t want the surface of your product to dry out and harden.

The hot smoker at The Salt Lick in Driftwood, Texas

When the surface of the meat is softer, smoke is able to penetrate the meat more deeply and effect a stronger smoky flavor. Water evaporating from the burning wood also heats up the smoking chamber to cooking temperature from 45°C to 80°C. It is important to note that the temperature of the smoking chamber is unrelated to the temperature of the pyrolysis that should be around 400°C to obtain a balanced smoke taste.

One of the amazing and enduringly mysterious things about smoke is that even if all the parameters influencing the smoke flavor — burning fuel, pyrolysis temperature, air flow, relative humidity — are the same, the smoke generated by hot smoking has a different flavor to the one generated by cold smoking.

The difference is likely due to the variation in the amount and type of phenols. Guaiacol, maltol, and eugenol are responsible for the respective spicy, malty, and clove-like notes present when cold smoking. By contrast, the hot process generates major amounts of acetovanillone and acetosyringone, the first contributing to faint sweet vanillin notes, the latter being odorless. Smoke in a hotter environment tastes sweeter (because of the acetovanillone), less delicate, and less complex than cold smoke, though the style works well with certain kinds of food.

Inspired by the yakitoris of Tokyo, and after a lengthy process of trial and error, the Copenhagen chef Matt Orlando figured out how to hot smoke lumpfish flesh, a product few restaurants use. “The only person I could find who has cooked it in the past is Erwin Lauterbach,” says the chef. At his restaurant Amass, Orlando salts the fish overnight for moisture and then hot smokes it with birch wood at 160°C for anywhere from 25 to 40 minutes.

SOME WORDS OF CAUTION

As with any cooking technique, smoking needs to be precise, not only for deliciousness but also for health. There are certain compounds produced in smoking that can have serious health effects, particularly Polycyclic Aromatic Hydrocarbons (PAHs), among which is the highly carcinogenic benzo[a]pyrene (BaP). A number of studies on smoked foods reveals that the highest levels of PAHs can be found in products from traditional kilns, where the combustion temperature is difficult to control and can be very high (above 450°C, the BaP level increases significantly). Traditional hot smoking methods have been shown to increase PAH levels by a factor of eight compared to traditional cold smoking.

Although some smoked fish products may contain large amounts of PAHs, smoked meats and fish do not generally contribute much to the human intake of these compounds. Nevertheless, the concentration of BaPs and PAHs may be reduced by using an untreated burning fuel, a pyrolysis temperature around 400°C, indirect smoking, no open fire, and a reduced smoking time. You should also work to optimize the moisture and air supply.

Coincidentally, most of these recommendations actually end up producing a better-tasting smoke.

ADDITIONAL READING

If you wish to dig deeper into the subject of smoking, here are some recommended titles:

Maga, J.A, (1988), Smoke in Food Processing, CRC press — A very precise and technical food industry smoking reference. Maga reviews the composition and flavor chemistry of wood and smoke. He describes different smoking techniques and their effects on flavor, texture, color, and preservation.

McGee, H. (2004), On Food & Cooking: an Encyclopedia of Kitchen Science, History and Culture, Hodder and Stoughton — A kitchen classic, always useful for understanding in an engaging way the history and basic chemistry of smoke.

Myhrvold, N. and al. (2011), Modernist Cuisine: the Art and Science of Cooking, The Cooking Lab, Vol 2, p 134 – 149 — A great reference for chefs and those who want to understand smoke as a flavor and master the techniques associated with that quest.

Ruhlman, M., (2005), Charcuterie: The Craft of Salting, Smoking and Curing, Norton & Company — A great book for beginners. Ruhlman’s writing is clear and engaging.

Strabridge, D., (2012), Made at Home: Curing and Smoking, Mitchell Beazley —Going back to the roots: smoking as a preservation method. Mostly based around cold-smoked products, this book teaches you how to keep meat and fish.

Siesby Birgit, (1997), Fish: Food from Waters, Oxford Symposium, p 280 – 282 — This fascinating anthropological paper explains the Scandinavian traditions of eating and preserving fish.

Toth, L., Blaas, W., (1972).The effect of smoking technology on the content of carcinogenic hydrocarbons in smoked meat products. Fleischwirtschaft, 52, 1419-1422 — An essential scientific paper that analyzes how different smoking techniques influence the deposit of Polycyclic Aromatic Hydrocarbon (PAHs) and their carcinogenic health risks.